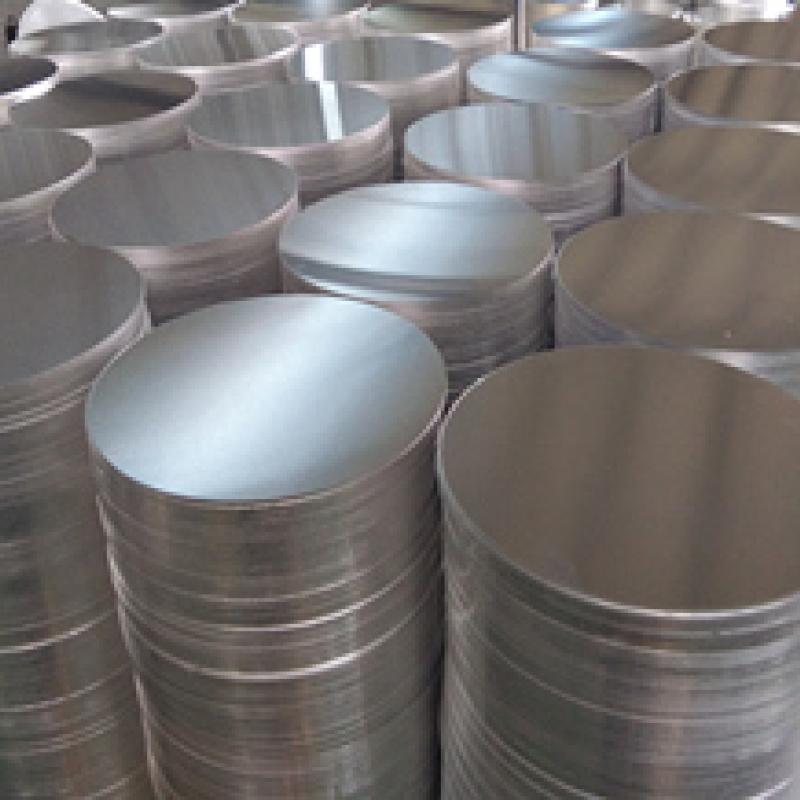

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical characteristics of the production line:1. CNC is fully automatic. This production line starts from uncoiling of coiled materials to the completion of blanking of the whole roll of materials.

Связаться сейчас

The company mainly deals in: aluminum plate, patterned aluminum plate, alloy aluminum plate, thermal insulation aluminum plate, aluminum oxide plate, brushed aluminum plate, color coated aluminum plate, aluminum coil, aluminum rod, aluminum tube, aluminum strip, aluminum foil and other products. Now the company has hot rolling production line, casting production line, cold rolling production line, shear machine, annealing furnace and other equipment. The company has passed the ISO9001:2000 system certification.

Связаться сейчас

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Связаться сейчас

purpose1. Lighting 2. Solar reflector 3. Building appearance 4. Interior decoration: ceiling, wall, etc. 5. Furniture, cabinets 6. Elevator 7. Signs, nameplates, bags 8. Interior and exterior decoration of cars 9. Interior decoration: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13, mold manufacturing 14, chemical/thermal insulation pipe coating. 15. High quality ship plate

Связаться сейчас

High quality insulation aluminum skin,Aluminium coil manufacturer,Aluminium coil dealer.What are the advantages of insulating aluminum skin?1, beauty, as the saying goes, "Buddha by gold, people by clothes", appearance wrapped with a layer of insulation aluminum skin, then the beauty of the pipeline is greatly increased, thermal insulation aluminum plate, thermal insulation aluminum skin, aluminum skin price,1060 aluminum plate, aluminum plate price with the current popular words is immediately "high".2, the main purpose of using thermal insulation aluminum skin is to exten

Связаться сейчас

Orange peel pattern aluminum plate is widely used in the following fields, such as lighting, solar reflective sheet, architectural appearance, interior decoration, furniture, cabinets, elevators, signs, nameplates, automobile interior and exterior decoration, interior decoration, household appliances, aerospace and military aspects, such as China's current large aircraft manufacturing, mechanical parts processing, mold manufacturing, chemical industry, thermal insulation pipe coating and other industries, It is believed that the application of embossed aluminum plate will be more extensive

Связаться сейчас

How to judge the quality of aluminum brick 1. Observe whether there are multiple scratches on the surface of the aluminum corrugated plate. Aluminum ceramic tile belongs to mechanical processing, which will inevitably lead to some scratches and scratches, but if it is too much, the beauty will be affected. Friends who have high requirements for the surface of aluminum ceramic tiles can also ask the manufacturer to carry out film coating processing in advance. 2.

Связаться сейчас

Also we would like to supply you some following more details about our part materials:1100 Aluminum SheetLow strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability. Readily to welding, brazing, and soldering. Machinability is poor and tends to be “gummy”. Non-heat treatable. Typical applicationsinclude chemical storage, processing equipment, kitchen utensils, and general sheet metal work. 3003 Aluminum SheetApprox.

Связаться сейчас

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is also known as pipe wrapped aluminum coil.

Связаться сейчас

Shandong Pingyin Chengye plate Co., Ltd. is a set of aluminum and aluminum alloy production and operation in one of the integrated enterprise, The main products are aluminum and aluminum alloy plate, aluminum coil, aluminum strip, aluminum foil, aluminum bar, aluminium pipe, aluminum wire, aluminum ingots and other products through the ISO9001: 2000 quality system certification. The company's prompt delivery, high quality and low price, service and thoughtful.

Связаться сейчас

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise referred to as pipe wrapped aluminum coil. There is rock wool insulation layer withinside the wrapped aluminum coil and pipe to shield the thermal diffusion of heating pipe, so it's far referred to as thermal insulation aluminum coil. Thermal insulation aluminum coil typically adopts 1100 aluminum coil and 1060 Aluminum Coil. If the carrier necessities are excessive and the carrier lifestyles is long, 3003 antirust aluminum coil may be used.

Связаться сейчас

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there's rock wool insulation layer in the wrapped aluminum coil and pipe to defend the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil commonly adopts 1100 aluminum coil and 1060 aluminum coil. if the provider necessities are excessive and the provider life is lengthy, 3003 antirust aluminum coil may be used.

Связаться сейчас

Basic InstructionAluminum coil can also be called antirust aluminum coil. The production process of 3000 series aluminum coil in China is relatively simple. 3000 series aluminum coil is mainly composed of manganese. The content is between 1.0-1.5. It is a series with good antirust function. It is commonly used in humid environments such as air conditioner, refrigerator and car bottom. The price is higher than 1000 series. It is a more commonly used alloy series.PackingApplicationSupport processing customization. Consult the manufacturer for price and attribute details.

Связаться сейчас

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveler, feeder, swing unit, special closed single point mechanical press, rapid die changing device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical features of production line:1. Numerical control is fully automatic. The production line does not need any manual contact with any labor and materials from the uncoiling of the coil to the completion of the blanking of the whole coil of materials.

Связаться сейчас

Shandong Pingyin Chengye plate Co., Ltd. is a set of aluminum and aluminum alloy production and operation in one of the integrated enterprise, The main products are aluminum and aluminum alloy plate, aluminum coil, aluminum strip, aluminum foil, aluminum bar, aluminium pipe, aluminum wire, aluminum ingots and other products through the ISO9001: 2000 quality system certification. The company's prompt delivery, high quality and low price, service and thoughtful.

Связаться сейчас

Basic Instruction1060 Aluminum plate is widely used in products with low strength requirements. Products are commonly used in signboards, billboards, building appearance decoration, bus body, wall decoration of high-rise buildings and factories, kitchen sink, lamp holder, fan blade, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave utensils, welding parts, heat exchangers, clock surface and disk surface, nameplates, kitchenware, decorations, reflective appliances, etc.SpecificationAI(%)Si(%)Cu(%)Mg(%)Zn(%)Mn(%)Ti(%)V(%)Fe(%)99,600.250.0

Связаться сейчас

Basic InstructionAluminum coil also can be known as antirust aluminum coil. The manufacturing manner of 3000 collection aluminum coil in China is quite simple. 3000 collection aluminum coil is particularly composed of manganese. The content material is among 1.0-1.5. It is a sequence with proper antirust function. It is generally utilized in humid environments along with air conditioner, fridge and vehicle bottom. The fee is better than a thousand collection. It is a extra generally used alloy collection.PackingApplicationSupport processing customization.

Связаться сейчас

Specific products are as follows:Aluminium (cold rolled sheet) (cold rolled aluminum sheet)Material 1060, 1100, 1050, 8011, 3003, 3004, 5052, 1145, 5083, 6061,Thickness 0.1mm---680mmWidth 800mm----3300mmAluminium coil (cold rolled coil)Material 1060, 1145, 1050, 12008011, 3003, 3004, 5052, 1100, 5083, 6061Thickness 0.10mm----10mmWidth 800mm----1900mmColor coated aluminum coil (embossed color coated aluminum coil (polyester): color coated aluminum coil, fluorocarbon color coated aluminum coil)Thickness 0.024-1.2 (mm) width 800-1220 (mm) 1100 1060 3003 5052

Связаться сейчас

Aluminum coil Production detail:1)Alloy: 1050,1060,1070,1100,1235, 3003,3004,3105, 5052,5083,5754, ,6061,80112)Temper: O ,H12,H22,H14,H24,H16,H26,H18,H32, H112 (F) , H111,etc.3) Specification: Thickness: 0.2-150mm Width: 20mm-2200mm &

Связаться сейчас

Our main products as below: 1..Aluminum sheet and aluminum plate Alloy: 1060,1100,1050,1145,8011,3003,3004,5052,5083 ,6061,Thickness: 0.1mm-680mm Width: 800mm-1900mm2.Aluminum coil/roll Alloy: 1060,1145,1050,1100,8011,3003,3004,5052 ,5083,6061Thickness: 0.10mm-10mmWidth: 800mm-1900mm 3..Aluminum strip Alloy:1060 1100 8011 3003a.Transformer special aluminum strip: Alloy:1060 temper:0 thickness:0.3-3.0(mm),b.Pipe aluminum strip: alloy 8011 temper: O

Связаться сейчас

Basic InstructionAluminum coil moreover can be known as antirust aluminum coil. The manufacturing method of 3000 collection aluminum coil in China is pretty simple. 3000 collection aluminum coil is in particular composed of manganese. The content material cloth cloth is among 1.0-1.5. It is a chain with actual antirust function. It is generally carried out in humid environments consisting of air conditioner, fridge and car bottom. The rate is better than one thousand collection.

Связаться сейчас

Specific products are as follows:Aluminium (cold rolled sheet) (cold rolled aluminum sheet)Material 1060, 1100, 1050, 8011, 3003, 3004, 5052, 1145, 5083, 6061,Thickness 0.1mm---680mmWidth 800mm----3300mmAluminium coil (cold rolled coil)Material 1060, 1145, 1050, 12008011, 3003, 3004, 5052, 1100,

Связаться сейчас

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there is rock wool insulation layer in the wrapped aluminum coil and pipe to guard the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil usually adopts 1100 aluminum coil and 1060 aluminum coil. if the company requirements are excessive and the issuer life is prolonged, 3003 antirust aluminum coil can be used.

Связаться сейчас

Thermal insulation aluminum coil plate (aluminum sheet) is actually a thin plate of aluminum, commonly known as aluminum coil plate. It can be delivered in flat or rolled form. Due to the poor iron sheet, in recent years, the insulation aluminum coil plate (aluminum sheet) has partially replaced the iron sheet.

Связаться сейчас